top of page

DATE:

INSTITUTE:

COURSE:

SKILLS:

Fall 2025

Duke University Pratt School of Engineering

Advanced Design & Manufacturing

• Design for Manufacturing

• 3D CAD Modeling (Autodesk Fusion)

• Rendering (Fusion, KeyShot)

• Finite Element Analysis

• Draft Analysis

Reimagined Cystoscope:

This project takes an innovative approach to reimagining the rigid cystoscope, balancing functional performance, usability, and manufacturability. The resulting design prioritizes clinician ergonomics and patient comfort through an intuitive grip and a refined, purposeful form.

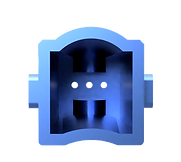

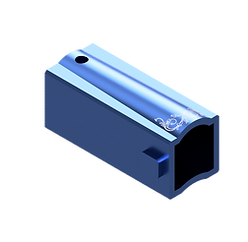

PART I: Photon Engine

The photon engine module is housed within the cystoscope and integrates the light source, camera, and laser.

2D Technical Sketch

2D Technical Drawing

Rendering

PART II: Cystoscope

Background:

A cystoscopy is a common medical procedure used to diagnose and treat conditions of the urinary tract. During the procedure, a rigid cystoscope is inserted through the urethra into the bladder while the patient is awake. Many existing rigid cystoscopes rely on outdated form factors that are difficult for clinicians to operate and offer limited consideration for patient comfort.

Redesign:

The goal of this project was to redesign the cystoscope to improve patient comfort and clinician usability. This was achieved through a design-driven process that included visual exploration, iterative sketching, and the development of a detailed 3D CAD model informed by design-for-manufacturing considerations.

Mood board for a patient-friendly medical device

Final Cystoscope Sketch

2D Technical Drawing

3D CAD Model

Integrated side buttons for one-handed valve actuation

Streamlined, minimal form optimized for handling and control

Contoured, ergonomic grip

Front

Side

Back

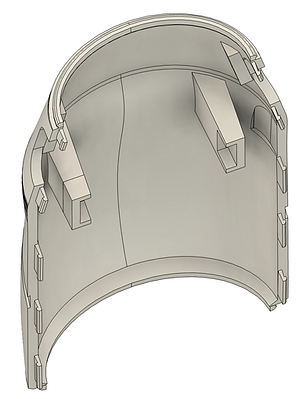

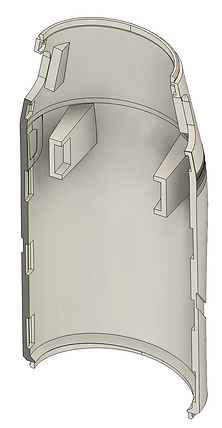

Internal Components:

Luer locks (inlet/outlet tubing for water flow)

3-pole electrical power connection

Mechanism to secure sheath

Mechanism to secure photon engine

Buttons integrated into body (flow valve control mechanism)

Assembly method:

Cantilever snap fits (front and back)

Annular snap fits (top and bottom)

Material:

PC/ABS blend (medical-grade)

Silicone (decorative curve, added separately)

Interactive 3D Model

Analysis:

Draft Analysis:

Evaluated taper of surfaces to ensure components are injection moldable.

Finite Element Analysis:

Applied a structural load of 20 N on tip of sheath (stainless steel).

Final Renderings

GALLERY

bottom of page