DATE:

INSTITUTE:

COURSE:

SKILLS:

Fall 2025

Duke University Pratt School of Engineering

Introduction to Rheology

• 3D CAD Modeling (SolidWorks)

• CFD Analysis (Flow Simulation)

• TRIOS Software (lab rheometer measurements)

• Data Analysis & Graph Modeling

A Rheological Analysis of Non-Newtonian Fluids in a Soap Dispenser

This study investigates how the rheological properties of three commercial liquid soaps, Aesop, Meyer’s, and Method, influence their performance within a standard consumer soap dispenser. Although pump dispensers appear mechanically simple, their usability depends on complex interactions between fluid behavior, pump geometry, and user-applied force. Rheometer testing was conducted to characterize each soap’s viscosity, shear-thinning behavior, and overall flow profile. These results were integrated into a computational fluid dynamics (CFD) analysis in SolidWorks Flow Simulation using an original computer-aided design (CAD) soap dispenser creation as the geometry governing the flow trajectory. The CFD analysis evaluated pressure distribution, shear rate, and viscosity changes under flow for a fixed inlet velocity representing typical pumping conditions. Resulting actuation force was derived from pressure drop and the geometrical dimensions of the CAD model.

The findings reveal substantial performance differences due to formulation chemistry. Aesop exhibited moderate viscosity and limited shear-thinning, resulting in the highest pressure drop and near-upper-limit actuation forces. Meyer’s, despite having the highest zero-shear viscosity, demonstrated strong shear-thinning behavior that reduced its dispensing resistance and placed its required force within the ideal ergonomic range. Method displayed minimal resistance but presented an undesirable Newtonian-like behavior under zero-shear conditions. Overall, Meyer’s proved most compatible with the tested dispenser geometry, highlighting how rheology and CFD together enable high-accuracy prediction of product performance and inform industrial design decisions regarding formulation choice, mechanical sizing, and user experience.

Background - Soap Formulation and Micelle Structure

Liquid soaps are structured fluids composed of surfactants, water, electrolytes, and fragrances that modify viscosity. Surfactants spontaneously assemble into micelles, whose size, packing, and shape determine the fluid’s resistance to flow. Small, freely moving micelles have low viscosity and Newtonian-like behavior, while large, elongated micelles have increased viscosity and are shear-thinning.

Foundation for Advancement in Conservation. “Soaps, Surfactants, and Detergents” (2008).

ResearchGate – “Schematic representation of surfactant behavior at the water-oil interface.”

Micelle structures give cleaning formulations their cleaning power. The hydrophilic head attracts water while the hydrophobic tail attracts oils, reducing surface tension and enable these substances to mix. This microstructure is essential for understanding why seemingly similar soaps produce dramatically different flow behavior under pumping.

Part I. 3D CAD Modeling - SolidWorks

A complete model of the pump dispenser was created in SolidWorks and rendered in Autodesk Fusion. The soap dispenser has 11 different components modeled entirely from scratch and inspired by existing designs. The CFD analysis was conducted using this specific CAD model.

Rendering in KeyShot

SolidWorks Animation

Animation in Autodesk Fusion

Part II. Rheometer Testing

Modern-day RSO Oscillatory Rheometer

Capillary tube viscometer

Commercial rotational viscometer

Saybolt viscometer

Early viscometers (ancestor of the rheometer)

Identified three different liquid soaps with varying material properties:

1. Aesop

2. Meyer's

3. Method

Visited the lab to run a steady shear sweep on the rheometer:

Gross Hall Laboratory

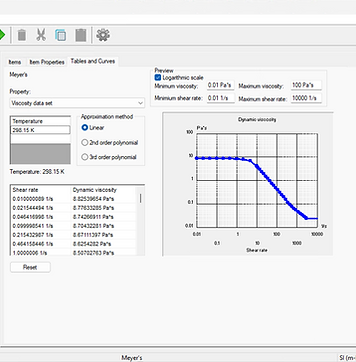

TRIOS Software: Viscosity vs. Shear Rate

Aesop sample

Meyer's sample

Method (not pictured)

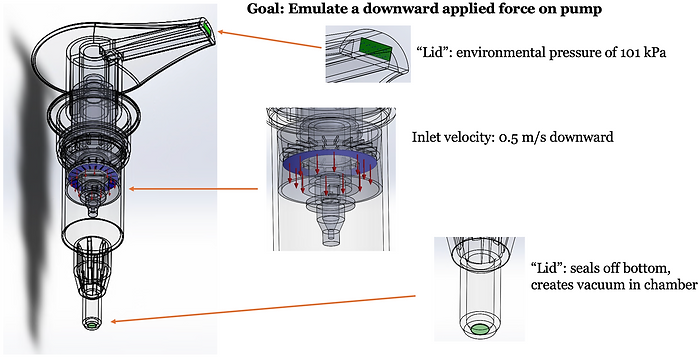

Part III. CFD Analysis - SolidWorks Flow Simulation

CFD analysis was performed on the SolidWorks soap dispenser model using SolidWorks Flow Simulation to replicate the fluid behavior during pump actuation. The objective was to simulate the downward force applied to the pump and analyze the resulting flow within the internal pump chamber that houses the spring mechanism. An inlet velocity of 0.5 m/s downward was chosen to represent a typical pump push.

YouTube - “How Soap Bottle Pumps Work"

Flow Simulation Boundary Conditions

Inputted rheometer data into SolidWorks to create a unique material profile for each soap sample (dynamic viscosity vs. shear rate)

Aesop

Meyer's

Method

Results - SolidWorks Flow Simulation

Velocity Flow Distribution

Due to a set initial velocity of 0.5 m/s, the velocity is relatively similar across samples

Aesop

Meyer's

Method

Pressure Flow Distribution

Aesop produced the highest pressure drop (~40 kPa), then Meyer's (~10 kPa), then Method (~3 kPa)

Aesop

Meyer's

Method

Dynamic Viscosity Flow Distribution

Aesop: moderate zero-shear viscosity (~1.6 Pa·s), moderate shear-thinning (drops to ~0.06 Pa·s)

Meyer’s: high zero-shear viscosity (~8.8 Pa·s), strong shear-thinning (drops to ~0.02 Pa·s)

Method: Newtonian-like, viscosity near 0.005-0.006 Pa·s across entire shear range

Aesop

Meyer's

Method

Shear Rate Flow Distribution

Aesop

Meyer's

Method

Parameters at Nozzle Openings

Evaluating a small control volume at the nozzle tip shows that Aesop exhibits the highest viscosity (~0.8 Pa·s), followed by Meyer’s (~0.1 Pa·s), with Method displaying the lowest viscosity (~0.005 Pa·s). Analysis of the wall shear stress along the upper interior surface of the nozzle further reinforces this pattern: Aesop produces the highest average shear stress (~320 Pa), Meyer’s generates a moderate value (~62 Pa), and Method results in the lowest (~10 Pa).

Aesop

Meyer's

Method

Results - Comparative Analysis

Actuation Force Calculation

An ideal actuation force of approximately 4-8 N (~1-2 lbf) was selected as the target for this design. Human thumb-force measurements show that adults can exert maximum voluntary forces of ~100-137 N (Choi 2020). A 4-8 N range therefore represents only 3-8% of typical thumb strength, aligning with widely accepted ergonomic practices for low-effort, repetitive actions. This range is also consistent with documented improvements in user comfort when activation forces in industrial pushbuttons were reduced from ~5 lbf (~22 N) to ~1-2 lbf (~4.5-9 N), which significantly lowered strain (Longmate 1996). Together, these findings support 4-8 N as a practical and user-friendly force range for consumer soap dispenser actuation.

The fluid force was calculated for each individual soap using their unique pressure distributions and the known cross-sectional area of the piston from the CAD model:

Piston Area

Calculated the total actuation force (force exerted by user for a downward pump push) for each soap:

The resulting actuation forces for each soap formulation are summarized below:

Viscosity vs. Shear Rate - Rheometer Data

Aesop and Meyer's observed behavior fit that of the Cross Model:

Altair – HW Desktop: “MFS – Cross-Model Scripting”

Shear Stress vs. Shear Rate - Rheometer Data

Conclusion

Fit for CAD Soap Dispenser?

The results indicate that Meyer’s demonstrates the strongest compatibility with the dispenser geometry, driven by its pronounced shear-thinning behavior and actuation force that remains comfortably within the ideal range. Aesop is also capable of flowing through the geometry; however, its comparatively higher viscosity at the elevated shear rates present in the simulation leads to greater resistance. Method dispenses with ease, but its Newtonian-like behavior and low viscosity at low shear rates result in a noticeably “watery” consistency upon exit, reinforcing that it is better suited for foam-pump dispensers.

Aesop’s formulation containing polymeric thickeners produces a smooth, premium sensory feel consistent with its luxury branding and higher price point. It has a moderate viscosity which does not significantly decrease under shear, allowing the soap to retain a thick, substantial feel when rubbed between the hands.

Meyer’s formulation containing a blend of surfactant-salt systems, indicative of long, entangled worm-like micelles, produces high viscosity at low shear rates and strong shear-thinning behavior, resulting in much lower viscosity under high shear. This combination enables a gel-like consistency during dispensing while keeping the formulation cost-effective, making it well-suited for everyday use.

Method’s Newtonian-like formulation, suggesting small, unstructured micelles, aligns with the functional requirements of foam-pump dispensers used by consumers who prefer foaming cleansers. Its formulation leverages high-foam surfactants that readily entrain air and pass through a fine mesh to generate foam. As a result, the formulation is intentionally optimized to meet the mechanical and fluid-dynamic constraints of foam-pump hardware.

Thank you!