top of page

DATE:

INSTITUTE:

COURSE:

SKILLS:

Fall 2025

Duke University Pratt School of Engineering

Experimental Design & Research Methods (Team Project)

• Hardware Design (Mechanical Structure, Electronics Housing)

• 3D CAD Modeling (SolidWorks)

• 3D Printing

• Robotics (Raspberry Pi)

This work introduces hydra, a slinky-inspired tendon-driven continuum robot (TDCR). Built from modular units that bend and flex through tendon actuation, the robot produces wave-like motion for locomotion. By applying tendon actuation to achieve slinky-like movement, hydra demonstrates a novel approach to mobile continuum robotics. This platform provides opportunities to investigate new forms of distributed actuation and bio-inspired locomotion, with potential applications in search-and-rescue, confined-space inspection, and soft robotics research.

HYDRA HARDWARE

Summary

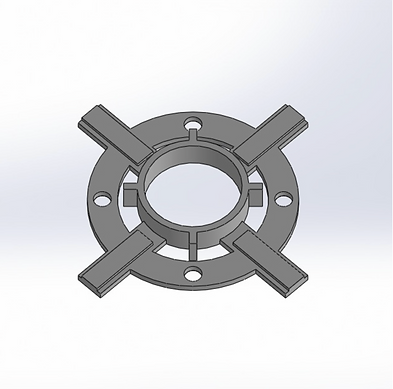

The hardware design of hydra includes both the mechanical structure and the integrated electronics housing. The robot’s body is formed using spacer discs, connectors, and support wings that align and constrain the tendon routing while maintaining structural flexibility. The end effectors serve a dual purpose: they act as the robot's "feet" for locomotion and also contain the electronics and wiring. All components were modeled in SolidWorks and manufactured using 3D-printed parts. The module unit design is adapted from a research paper by the Continuum Robotics Laboratory at University of Toronto.

Spacer Discs and Connectors

Our spacer disk design was inspired by a tendon-driven robot developed by the Continuum Robotics Laboratory, which uses a lightweight modular segment architecture with pre-programmable stiffness. The spacer discs divide the robot into individual segments, each with its own bending behavior and flexibility. We adapted this concept for hydra by scaling the discs to a 10 mm outer diameter, ensuring sufficient space for tendon routing while maintaining structural stability. The connectors are integrated with the spacer discs to secure the support wings and maintain alignment throughout the structure.

Spacer Disc

Connector

Support Wings

The support wings were also based on the Continuum Robotics Laboratory robot, which uses angled wings to provide structural support while allowing a spring-like flex during bending. Given the mobile nature of our robot, we needed to increase the flexibility of the support wings to allow for a sufficient bending range. To achieve this, we modified the initial design by increasing the wing length, which required adjusting the fundamental wing geometry. These changes improved the overall bendability of each segment while maintaining structural support.

Initial Support Wing

Final Support Wing

Module Unit Assembly

Each module unit assembly consists of two spacer discs, two connectors, and four support wings. These assemblies form the individual bending segments of the robot's structure. The following diagram illustrates the progression of our module unit designs over time.

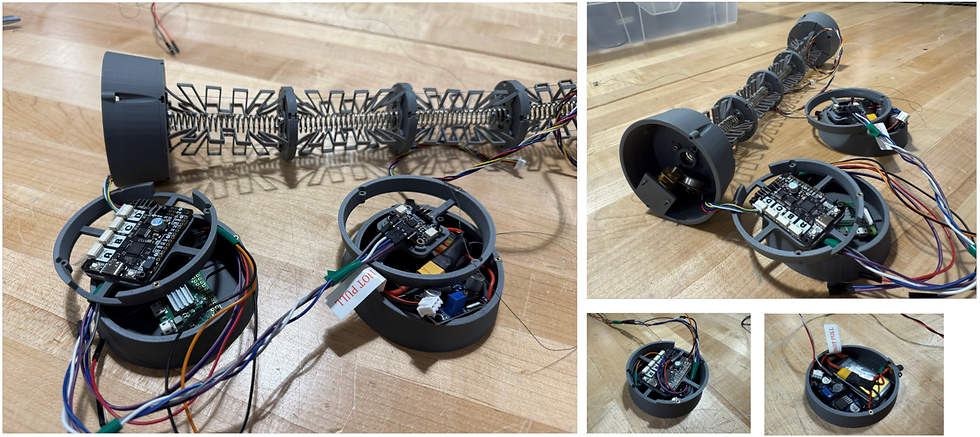

End Effectors

Our end effectors function both as the robot's method of locomotion and as the housing for the electronics. We designed them to be as compact as possible while still providing sufficient internal space for all components. The end effectors are divided into three stacked layers, each connected using counterbored fasteners to securely enclose and organize the electronics. The following diagram shows the progression of our foot unit designs over time.

Electronics Housing

The internal structure of the end effectors serves as the housing for all electronic components. We mounted each component to its designated layer with snug fits and screws to keep everything firmly in place during motion and transportation.

Full Robot Subassembly

The final subassembly (v6) of all the hardware components, with a description of the electronics housing, is shown below.

Full Robot Assembly

Using four connected module units, two end effectors, and a compression spring as the backbone, our full robot assembly is shown below.

Teleoperation Demo

• Raspberry Pi and motor controller

• Uses antagonistic actuation

Future Work

• Replace current electronics with smaller form factor for more compact / lighter design

• Experiment with more compliant filament such as TPU or TPE

bottom of page